DOWNFLOW CONTAINMENT BOOTHS

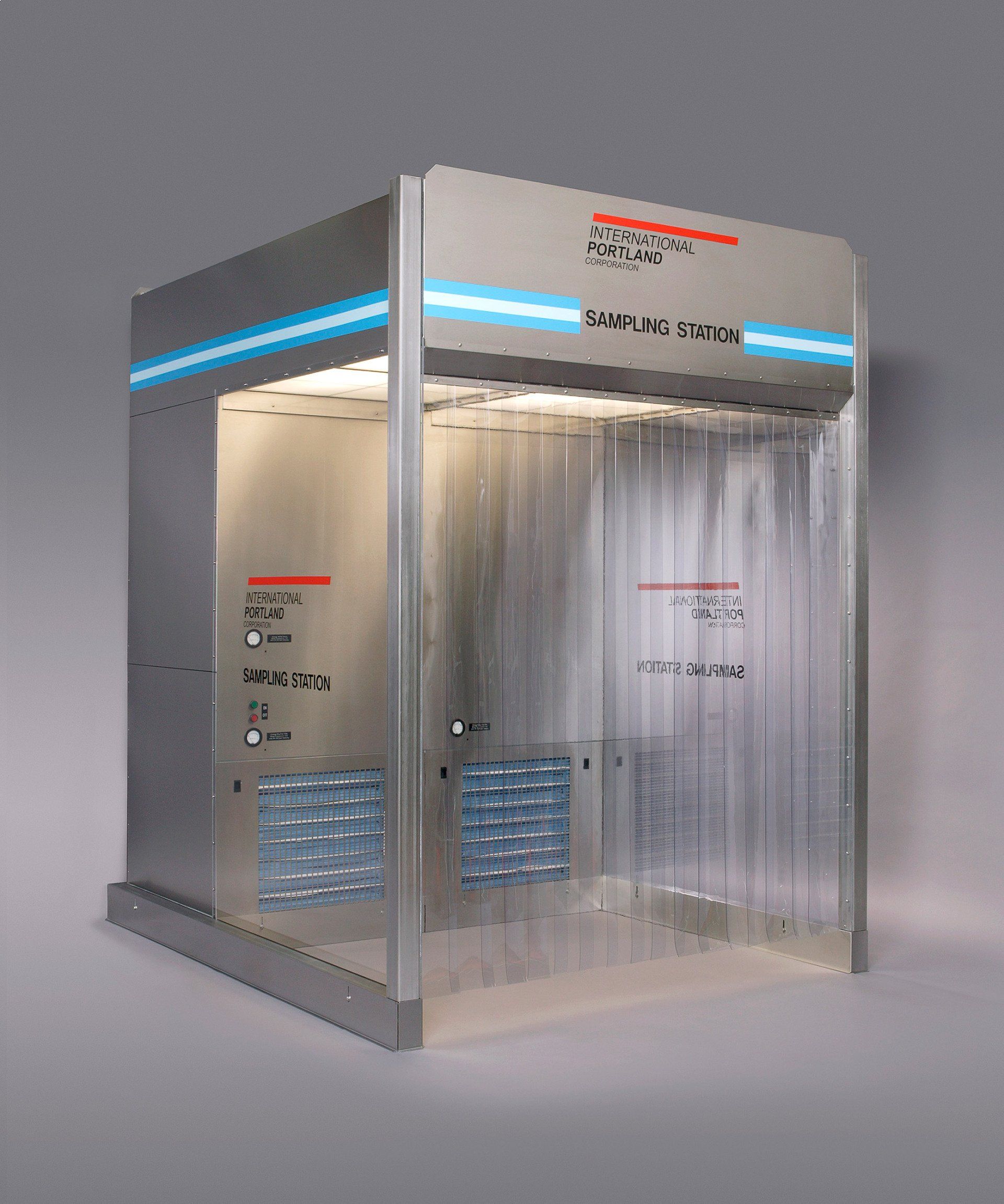

Model 895 Modular Down-Flow Containment Booth

DOWNFLOW CONTAINMENT BOOTHS THAT MAKE THE DIFFERENCE

in pure raw material sampling and worker safety

In today's environment you can't take chances with raw material contamination or your workers' safety.

With 30 years of experience, International Portland has set the standard for mobile localized clean air (mini-environments) and downflow containment booths by exceeding customer needs and industry standards - developing ISO 5 environments. International Portland's products greatly decrease the risk of product cross contamination and increase workers safety.

DOWNFLOW CONTAINMENT BOOTHS PROVIDE WORKER & PRODUCT SAFETY

STANDARD FEATURES

- Occupational Exposure Level (OEL) < 20 ug/m³

- Recirculating

- Negative Pressure Containment Area

- Class 100 Air (ISO 5)

- Available in Widths of 5’ & 3’ and Depth Increments of 3' & 5’ (15’ Depth Maximum)

- Membrane Diffuser Ceiling

- LED Lights

- 304 Stainless-steel Construction

- Variable Frequency Drive (VFD)

OPTIONAL FEATURES

- Class I DIV I, DIV 2 or Class II Explosion Proof

- One Pass Air

- Chilled Water or Air Conditioning Cooling

- Human Machine Interface (HMI) With Status & Alarms

- Automatic Airflow Control

- Gowning and De-Gowning Rooms

- Entry by Swing Doors, Roll-up Doors

BENEFITS

- Provides Operator and Product Safety

- Warehouse Material Sampling

- Meets FDA or euGMP Requirements

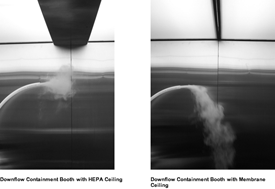

- All downflow containment booths feature Class 100 (ISO 5) HEPA filtered air at 90-100 fpm over the entire ceiling, resulting in no updrafts that would contaminate pure raw materials and endanger workers' safety.

- Pre-filter intakes at low levels provide ISO 5 air over small drums as well as large containers.

- Negative pressure in the booth prevents cross contamination and material from escaping to the outside.

- Smooth cavity-free containment walls allow for easy wipe down.

- All models are covered by a three-year warranty.

- All products are designed for long-term use and are of the highest quality construction.

DOWNFLOW CONTAINMENT LIST

Here is a list of some of the customers we have supplied units:

- Lilly del Caribe

- McNeil Healthcare

- Johnson & Johnson

- Amgen Manufacturing Inc.

- Aventis Pharmaceuticals

- Colorcon

- GlaxoSmithKline

- Legacy Pharma

- Pfizer Global Operations

- Merck Sharp & Dohme

- Patheon PR Operations

- FDAH

- Xoma

- Human Genome Sciences

- Cardinal Health

- Gilead Sciences

- Baxter Healthcare

- Bestco

- Becton Dickinson

- Celltech

- Lyne Laboratories

- UPS Supply Chain Solutions

- Thermofisher